800-811-4403

sales@petsinc.net

sales@petsinc.net

Thermoplastic-Analysis.com

Plastic Engineering And Technical Services, Inc.

........... Flash Movie & Text Will Be Replaced

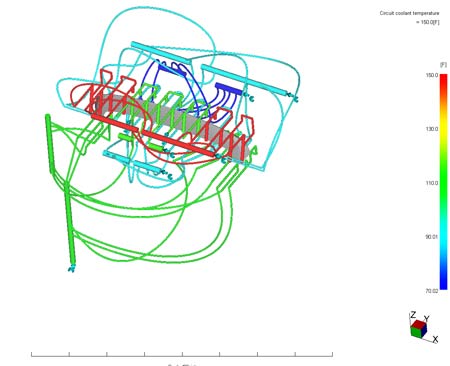

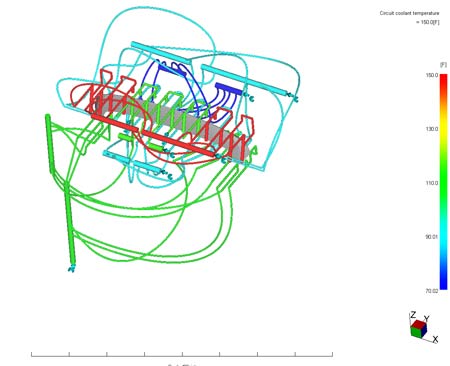

MoldFlow

In order to achieve superior part quality, we recommend conducting a cooling analysis.

We assure you that the cooling analysis will assist in perfecting design development

by achieving:.

◊ Large process window

◊ Minimum mold temperature differences

◊ Faster cycle time

◊ Uniform part surface from core to cavity temperatures

◊ Balanced flow rate

◊ Better dimensional stability and control

◊ Energy savings

◊ Optimize water line locations

We assure you that the cooling analysis will assist in perfecting design development

by achieving:.

◊ Large process window

◊ Minimum mold temperature differences

◊ Faster cycle time

◊ Uniform part surface from core to cavity temperatures

◊ Balanced flow rate

◊ Better dimensional stability and control

◊ Energy savings

◊ Optimize water line locations

The CAE team will provide mold cooling analysis service that will provide critical data to

achieve optimal cooling of the mold. This predictive analysis can increase part quality,

improve operation performance and generate cost savings.

Understand Effectiveness of:

◊ Waterline location

◊ Water Temperatures

◊ Water Flow Perimeters

◊ Mold Inserts

◊ Mold Temperature Distribution

© 2012 Plastic Engineering & Technical Services, Inc. all rights reserved